-

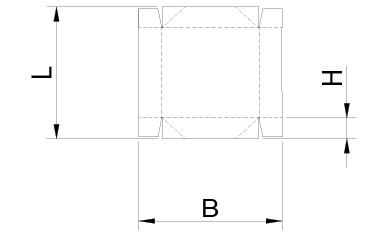

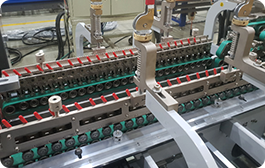

Carton Aligner Section

It aligns the blank that was fed from the feeder at any speed / The Carton Alignment section is an essential option for accurate folding, gluing and braille works.

-

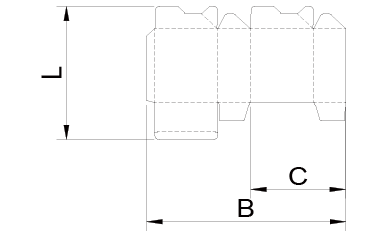

Turning Station (Gyro)

It turns blanks up to 180° as well as 90° so that operators can produce difficult boxes very easily and speedy with only one running machine.

It is mandatory for production of cartons like beer carrier cartons.

-

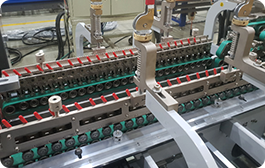

Auto-jog

The setting time can be significantly shortened by automatic setting of carriers. It eliminates the stress and time consuming of settings and it has unlimited data space to input,

store and recall setting values regardless of the size and number of workpieces.

-

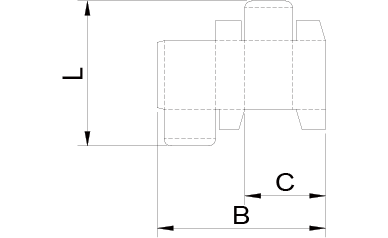

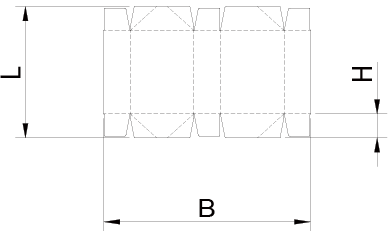

4/6CS, 8CS Back Folding

Ace Machinery Co., Ltd. Developed with its own technology, 4/6 C/S and 8C/S servo back folding device.

50,000 sheets per hour can be produced through this device and German servo motor and drive. (World's first) / Simple operation is available just by inputting distance, angle, speed

-

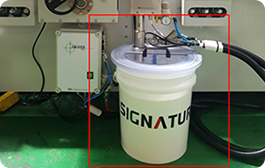

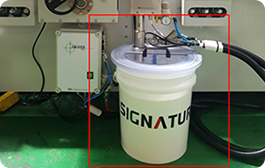

Glue Supply Device

It does not require frequent replacement of the glue due to large storage, and the sensor does not cause a no-glue phenomenon because of the correct amount of glue supply.

This reduces work time and increases productivity. You can use it cleanly without worrying about overflowing because the pump automatically feeds the glue without putting the glue directly.

-

Spanker

It is a device that maintains the consistency of the quality of the loading and the alignment of the blank by correcting disorder and scattering of folded cartons when produce thick blanks.

Eagle

Eagle