-

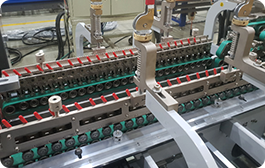

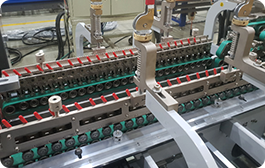

Carton Aligner Section

It aligns the blank that was fed from the feeder at any speed / The Carton Alignment section is an essential option for accurate folding, gluing and braille works.

-

Fastfold

FAST FOLD is a device that folds the flap of the folding line naturally by using the wave of the vacuum, not the hook-folding method when produce the cratons.

The conventional hooking method is limited by the inertia of the spring, which makes it impossible to increase the speed of the folding carton gluer.

However, this method using wave is not affected by the inertia and gives the users productivity up to 70,000 times per hour without restriction of speed.

-

Auto-jog

The setting time can be significantly shortened by automatic setting of carriers. It eliminates the stress and time consuming of settings

and it has unlimited data space to input, store and recall setting values regardless of the size and number of workpieces.

-

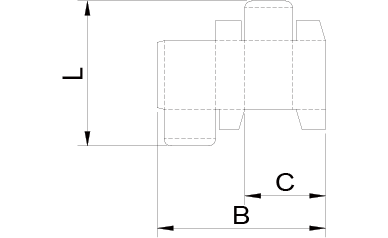

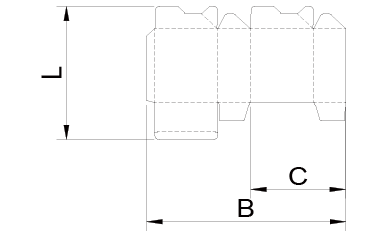

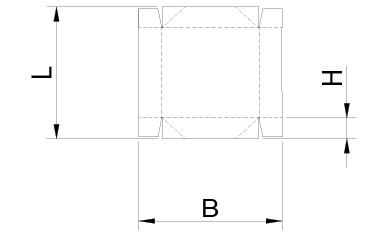

4/6CS, 8CS Back Folding

AAce Machinery Co., Ltd. Developed with its own technology, 4/6 C/S and 8C/S servo back folding device.

50,000 sheets per hour can be produced through this device and German servo motor and drive. (World's first) / Simple operation is available just by inputting distance, angle, speed.

-

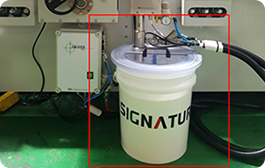

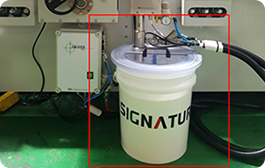

Glue Supply Device

It does not require frequent replacement of the glue due to large storage, and the sensor does not cause a no-glue phenomenon because of the correct amount of glue supply.

This reduces work time and increases productivity. You can use it cleanly without worrying about overflowing because the pump automatically feeds the glue without putting the glue directly.

-

Ejector

Reducing the defect rate of the blank is the key to production efficiency. Ace Machinery Co., Ltd. is able to detect the type and cause of defects without wasting time by detecting defects differently

from other companies through ACE's unique technology and patented ejector. Do not bend your waist or stop the machine to check for any further defects.

Ace

Ace